Digitalisation of the company: Digitalising business processes and implementing the "Industry 4.0" approach

Why call upon NosakiiS Group to digitalize your company?

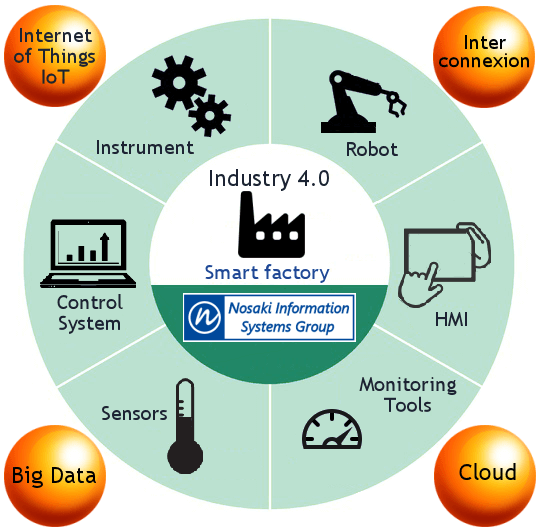

Thanks to its activities in digital technologies as well as in industrial IT, NosakiiS Group is the ideal provider to help you in your digitization process because we have a technological experience of all the elements of an Industry 4.0 implementation: Automation, robotics, process control, data acquisition systems, Internet of Things, databases, network infrastructures, Big Data, etc. NosakiiS Group offers you support at each step of your "Industry 4.0" project. Both in the analysis phase and in the actual implementation of technical solutions. NosakiiS Group works closely with your teams to define the scope of the project, identify the optimal solutions and plan their implementation. NosakiiS Group performs for you the following tasks:

NosakiiS Group offers you support at each step of your "Industry 4.0" project. Both in the analysis phase and in the actual implementation of technical solutions. NosakiiS Group works closely with your teams to define the scope of the project, identify the optimal solutions and plan their implementation. NosakiiS Group performs for you the following tasks:

- Technology consulting

- Audit of work processes to be digitised

- Feasibility study with cost estimate

- System architecture and technology choices

- Development of digital solutions

- Integration and implementation

- Staff training

The digitalisation of the company and its challenges

The digitalisation of the company consists in automating the tasks carried out within the company in order to reduce operating costs and optimise productivity gains.

The digitalisation of the company is not limited to the robotisation of industrial production or the digitalisation of business processes, it is about adapting its products and rethinking the company's business model based on innovative digital concepts and tools: "Industry 4.0" concept (digitalisation of manufacturing companies), Big Data (mass data processing), Cloud (remote digital storage), connected objects (Internet of Things), social media, artificial intelligence (AI), manufacture of parts by 3D printer, etc.

Digitalisation of processes is not a turnkey solution that can be simply implemented. For each company, it is necessary to identify the areas where digitalisation can be positive. The extent to which process digitalisation offers real efficiency must be assessed. Particular attention should be paid to the relationship between the expected benefits and the risks arising from the increasing complexity of the system.

The digital transition of the economy greatly increases the vulnerability of the company by multiplying the risks of data theft or unwanted takeovers. Particular care must be taken to ensure data security and the protection of the company's know-how.

Why should the "Industry 4.0" concept be applied?

At the beginning of the 21st century, Swiss industry is faced with numerous challenges such as the consequences of the strong franc, the cost and availability of labour, increased competition from low-cost countries, the need to save energy and the scarcity of certain resources. In addition, the digital transformation of society is revolutionising consumer habits and rendering whole sections of the traditional economy obsolete.

Companies must therefore adapt quickly if they do not want to be left behind.

The concept of "Industry 4.0" introduces a revolution in the business model related to the marketing of the product: The company no longer only sells the product, but also values the information related to it and can thus sell a service in the long term.

The aim is to improve the company's management and processes, to shorten lead times, to have a more flexible production tool in order to meet the demand for customised products, and to manage resources and raw materials in the best possible way, thus offering new productivity gains.

"Industry 4.0: From concept to factory of the future

The "Industry 4.0" concept consists of organising the means of production in the form of smart factories, allowing for optimal production flexibility and a more efficient allocation of resources.

It is in fact a question of digitising the traditional factory by means of new information and communication technologies (intelligent robots, autonomous systems, sensors, connected objects (Internet of Things)) to make it an organism that communicates and reacts with the outside world. It is not just about automating production processes: it is about closely linking operators, machines and data from product design to manufacture, distribution, maintenance and recycling. Throughout its life, the product provides data that is collected and used to improve processes or offer new related services.

It is in fact a question of digitising the traditional factory by means of new information and communication technologies (intelligent robots, autonomous systems, sensors, connected objects (Internet of Things)) to make it an organism that communicates and reacts with the outside world. It is not just about automating production processes: it is about closely linking operators, machines and data from product design to manufacture, distribution, maintenance and recycling. Throughout its life, the product provides data that is collected and used to improve processes or offer new related services.

The smart factory as imagined by "Industry 4.0" is characterised by the interconnection of systems at the production site and with its external stakeholders such as customers, suppliers or other production sites.

The term "Industry 4.0" refers to the 4th industrial revolution: After mechanisation, electrification and automation, the manufacturing industry is facing a new challenge - digitalisation.